Fire Sprinkler Guard Manufacturer

Buy or Customize sprinkler guards for your fire sprinklers in SD FIRE SPRINKLER.

SD Sprinkler Guards

At SD FIRE SPRINKLER, we specialize in the design and manufacture of high-quality fire sprinkler guards. Our guards are designed to protect your sprinkler systems from damage and ensure they function flawlessly in emergencies. Trust in our reliable guards to enhance the durability and efficacy of your sprinkler systems.

G1 Sprinkler Guard

Model G1 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

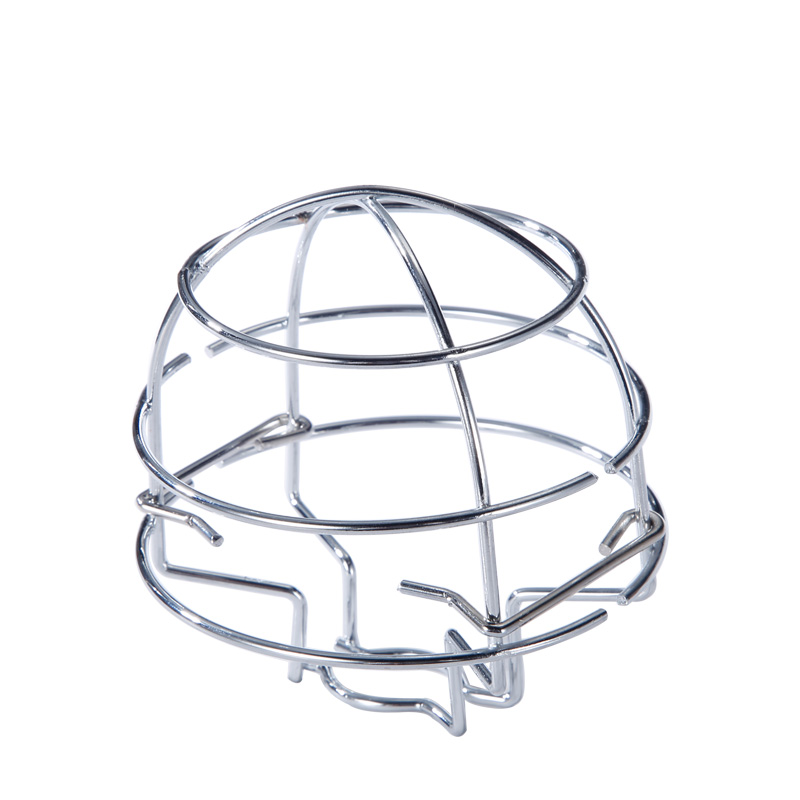

G2 Sprinkler Guard

Model G2 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

G6 Sprinkler Guard with Shield

Model G6 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

G3 Sprinkler Guard

Model G3 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

G4 Sprinkler Guard

Model G4 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

G5 Sprinkler Guard with Shield

Model G5 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

G9 Sprinkler Guard with Shield

Model G9 | 1/2'' or 3/4'' | Cold-roll Steel | Chrome Plated or Red Coated

ODM & OEM for Sprinkler Guards

Contact us to Customize your Sprinkler Guards

Why Choose Sprinkler Guards from SD FIRE SPRINKLER?

SD FIRE SPRINKLER is the specialized manufacturer of fire sprinkler systems since 1997. Our team is well equipped to provide you with professional advice, high-quality products, and customized solutions.

- Diverse Models

We offer a variety of sprinkler guard styles to complement different sprinkler types. Many popular models are readily available in stock for quick shipment.

- Professional Team

We pride ourselves on providing fast & practical project advise and efficient & reliable customization service.

- Rich Experience

We have successful experience collaborating with major brands, and our sprinkler guards have been well-recognized in the market for years.

How to Customize Your Sprinkler Guards?

- Customize according to YOUR Drawings

After receiving your drawings and brand authorization, our team will verify the details and manage the entire process, from mold creation and sample production to testing, final sample approval, manufacturing, and packaging. We guarantee that every aspect, including functionality, appearance, and packaging, aligns with your specific requirements.

- Customize according to YOUR Samples

If you lack detailed drawings but have a sprinkler guard sample that fits your project’s specifications, send us the sample and its corresponding sprinkler. We will create a new drawing from these items and then advance to sample production and bulk manufacturing accordingly.

- Customize based on OUR Existing Models

Utilizing our wide selection of existing sprinkler guards, we offer micro-customization options that enhance the product without altering the original design. These options include surface treatments, brand engraving, laser marking, and personalized packaging, tailored to your specific requirements. Micro-customization provides the advantages of low investment and rapid delivery.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Fire Sprinkler Guards

What are fire sprinkler guards?

Fire sprinkler guards are robust, hard-wire cages specifically designed to protect sprinkler heads from mechanical damage in active or industrial environments. These guards are essential for safeguarding the sprinklers against accidental impacts that could impair their functionality. Complementary water shields are utilized to block water from higher-level sprinkler, preventing premature cooling and delaying the activation of the shielded sprinkler. Together, these protective accessories are crucial in maintaining the reliability and effectiveness of fire sprinkler systems in challenging settings.

Why Install Fire Sprinkler Guards?

Protection Against Mechanical Damage:

Sprinkler heads are typically exposed and can be vulnerable to accidental impacts during routine activities or maintenance operations in areas like industrial settings, parking garages, stadiums, or warehouses. Sprinkler guards encase the heads, shielding them from being hit, knocked, or tampered with, thus preventing malfunction.

Maintaining System Integrity and Reliability:

A damaged sprinkler head can fail to activate during a fire, leading to catastrophic consequences. Guards ensure that the heads remain intact and functional, thereby upholding the system’s reliability when it matters most.

Cost-Effectiveness:

The cost of replacing a damaged sprinkler head goes beyond just the price of the head itself. It includes potential water damage from accidental activation, increased insurance premiums, and the possibility of system downtime. Installing guards is a relatively inexpensive way to avoid these costs and extend the lifespan of your sprinkler system.

Compliance with Safety Standards:

National and local codes often require or recommend sprinkler guards in certain settings to maintain system integrity. These regulations aim to protect building occupants and minimize fire risks. Complying with these standards not only enhances safety but also shields building owners and managers from legal and insurance repercussions of non-compliance.

Sprinkler Guard Types and Applications

Standard Sprinkler Guards

Standard sprinkler guards are the most common type, crafted to safeguard the majority of non-recessed pendent, upright, or horizontal sidewall sprinklers. Made from durable metal wires in a cage-like shape, they create a robust physical barrier around the sprinkler heads. These guards are designed to protect against general impacts, making them well-suited for most industrial, commercial and residential environments.

Recessed Sprinkler Guards

Recessed sprinkler guards are designed with an extended base that securely fastens to the threaded connection of a recessed fire sprinkler. These sprinklers are set within a recessed escutcheon with a subtle indentation, positioning the sprinkler frame just below the ceiling or wall surface. This design provides adequate protection for recessed sprinklers while maintaining their nice appearance. They are a good choice for environments such as hotels, hospitals, shopping malls, office buildings etc..

Sprinkler Guards with Shields

Sprinkler guards with shields are designed for dual functionality: they protect sprinklers from physical damage, and shield the sprinklers’ heat-sensing elements from water spray discharged by higher positioned sprinklers. These guards are primarily used in intermediate level or in-rack storage sprinkler systems. Additionally, they are suitable for various other applications, such as under grating, or in outdoor environments where they serve as weather shields.

*The single shield, without a cage, can be used for pendent sprinklers where there is no risk of mechanical damage, serving to protect the water spray from higher elevation sprinklers.

Heavy-duty Sprinkler Guards

Heavy-duty sprinkler guards are more robust protective devices designed to shield sprinklers from accidental activation in high-risk areas such as industrial facilities, warehouses, and sports arenas etc.. These guards attach directly to sprinkler pipes, ceilings, walls or in-rack beams, providing an extra layer of security against severe mechanical damage from heavy or fast-moving objects. While standard sprinkler guards offer protection against general impacts, heavy-duty guards are crucial in environments where potential damage could be severe and lead to costly repairs.

Guards Materials and Design Considerations

Carbon steel and stainless steel are the primary materials used for sprinkler guards. Analyzing and comparing their properties, along with their costs, will help you select the most appropriate guard for your project.

- Carbon Steel

Carbon steel, renowned for its strength, durability, and cost-effectiveness, is the primary material used in manufacturing sprinkler guards in the field. To enhance its anti-rust & anti-corrosion properties and aesthetic appeal, surface treatments are necessary. Carbon steel guards are now commonly used across a variety of regular fire sprinkler system projects.

- Properties: Good strength and durability

- Pricing: Moderate price

- Finishes: Chrome-plated, Zinc-galvanized, Powder-coated

- Stainless Steel

Stainless steel stands out for its exceptional corrosion resistance and ductility, making it the ideal material for sprinkler guards in environments with high humidity or substantial exposure to water and chemicals. In terms of performance, stainless steel guards do not require surface treatment. However, for enhanced visibility and aesthetic appeal, powder coating is also applied.

- Properties: Excellent anti-rust and anti-corrosion capabilities

- Pricing: Relatively high

- Finishes: Plain unpolished, Powder-coated

Surface Treatments for Guards

Chrome Plating

Chrome plating is the preferred surface treatment for guards, primarily serving to prevent rust and corrosion while enhancing appearance. It also increases the surface’s hardness and durability, thereby extending its lifespan. The treatment results in a bright, reflective silver finish. However, due to the complex processes and materials required, chrome plating can be relatively expensive.

Zinc Plating

Zinc plating is another effective treatment known for its excellent corrosion resistance. This process coats the metal with a thin layer of zinc, which acts sacrificially when exposed to oxidizing agents, thereby protecting the underlying iron or steel from rust. Zinc plating is generally more cost-effective than chrome plating and provides a decent silver white finish, although it is typically less shiny and reflective.

Powder Coating

Powder coating is a process where powdered paint is electrostatically charged and sprayed onto the metal surface, then cured under heat to form a hard layer. This coating is highly valued for its durability and resistance to scratches and corrosion. Available in a wide range of colors, powder coating offers flexibility in design options. The cost of powder coating is comparable to that of chrome plating.

How to Choose the Right Sprinkler Guards?

- Compatibility

First, ensure the sprinkler guards are compatible with your sprinkler heads by checking the thread size—common sizes include 1/2”, 3/4”, and 1”. Choose guards that match the thread size for a secure fit. Additionally, there are many types of Sprinkler guards available. Standard guards work with most sprinkler types, offering versatility, while sprinklers with shields are specifically for upright or pendent sprinklers and may not suit other types. It’s important to note that some brands specify compatible guard models; always consult your sprinkler manufacturer for precise guidance. If unsure about compatibility or other concerns, seek advice from a specialist in fire sprinklers and guards.

- Environments

It’s also necessary to consider the environments where the sprinklers are installed. In areas with high humidity or significant exposure to water and chemicals, opt for stainless steel guards. For sprinklers in high-risk settings like warehouses, factories, or sports venues, where there is a constant risk of impacts from moving machinery, heavy objects, or high-speed objects, it is better to use heavy-duty sprinkler guards.

General Installation Guidlines

Different types of sprinkler guards each require specific installation processes. For clarity, we have categorized the guards into four types, each described separately based on their general installation methods:

Standard Sprinkler Guard & Sprinkler Guard with Assembled Shield

Ensure the sprinkler is installed on the system prior to guard installation.

Begin by removing the retaining ring or loosening the clips.

Slightly spread the guard open just enough to encase the sprinkler frame and deflector. Align the base of the guard parallel to the sprinkler wrench boss.

Reattach the retaining ring or securely fasten the clips into the designated slots on the guard’s wires.

Sprinkler Guard with Separate Shield

Install the water shield on the sprinkler before attaching the guard. Note that the shield should be assembled onto the sprinkler prior to installing the sprinkler into the sprinkler fitting.

Proceed with installing the guard.

Ensure that both the guard and the shield are securely attached to the sprinkler.

Heavy-duty Sprinkler Guard

Ensure the sprinkler is installed on the system prior to guard installation.

Align the guard over the sprinkler, ensuring it does not touch the sprinkler head.

Attach the guard directly to the sprinkler pipe, ceiling, wall, or in-rack beam, and firmly fix the guard.

Verify the guard is stable and securely attached without obstructing the sprinkler head.

Water Shield Only

Attach the water shield to the sprinkler before it is mounted on the system.

Install the sprinkler assembly into the sprinkler fitting.

Adjust the position of the shield so that it is flush with the sprinkler’s mounting hardware, ensuring a secure fit.

Additional Installation Notes:

- Installation Guidance: Always follow the manufacturer’s specific installation instructions to ensure proper setup.

- Post-Installation Inspection: After installation, thoroughly inspect to ensure correct alignment and secure fastening.

- Testing: Perform a functional test to confirm that the installation does not hinder the sprinkler’s performance.

- Ongoing Maintenance: Regularly inspect and maintain the guard as per the manufacturer’s guidelines to guarantee its effectiveness and adherence to safety standards.

Frequently Asked Questions

Find Answers to Nearly All Your Sprinkler Guards Queries Here.

Fire sprinkler guards are designed to protect sprinkler heads from mechanical damage, especially in environments where they are susceptible to impacts from equipment or debris.

While not universally required by all codes, fire sprinkler guards are often recommended or mandated in industrial settings, warehouses, and other locations where the potential for sprinkler head damage is high.

Select a sprinkler guard that is compatible with the size and type of your sprinkler heads. Ensure that the guard is appropriate for the specific environmental conditions of the installation area, such as exposure to chemicals or extreme temperatures.

Yes, sprinkler guards can be installed on all types of sprinkler systems, including wet, dry, and pre-action systems. However, ensure the guard matches the specific requirements and configurations of your system.

When installed correctly, sprinkler guards do not impair the operation or effectiveness of fire sprinkler systems. They are designed to allow full water coverage and proper functioning of the sprinklers.

Sprinkler guards are typically mounted directly onto the sprinkler or attached to surrounding structures like pipes, ceilings, or walls. Installation involves securing the guard around the sprinkler head and ensuring it is firmly in place without obstructing the sprinkler’s operation.

Generally, sprinkler guards do not require regular maintenance. However, it is important to verify the proper installation of the sprinkler guards and shields during the annual visual inspection of the sprinklers. Please always refer to the local codes for inspection, testing and maintenance requirements for fire sprinklers and sprinkler guards.

Replace any damaged or compromised guards immediately to ensure continued protection of the sprinkler heads. When removing damaged guard and replacing them with new one, take care to avoid damaging the fire sprinkler.

Request A Free Quote

Our expertise is here to serve you!

We'de like to work with you!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right sprinkler escutcheons you want.

- Tel: +86-574-62357189

- Mob: +86-18867874188

- Email: info@shundanfire.com