Fire Sprinkler Cover Plate Manufacturer

Customize and purchase fire sprinkler cover plates directly from SD FIRE SPRINKLER.

SD Sprinkler Cover Plates

At SD FIRE SPRINKLER, we specialize in manufacturing and customizing fire sprinkler cover plates for concealed sprinklers. Our advanced facilities and over 25 years of expertise allow us to offer bespoke solutions that perfectly align with your functional and aesthetic needs.

CP1 Thread-on Cover Plate

Model CP1 | 135℉/57℃ or 165℉/74℃ or Customized | Brass | White coated or Customized

CP2 Thread-on Cover Plate

Model CP2 | 135℉/57℃ or 165℉/74℃ or Customized | Brass | White coated or Customized

CP3 Twist-lock Cover Plate

Model CP3 | 135℉/57℃ or 165℉/74℃ | Brass | White coated or Chrome Plated or Customized

CP4 Thread-on Cover Plate

Model CP4 | 135℉/57℃ or 165℉/74℃ | Brass | White coated or Natural Brass or Customized

How to Customize Your Sprinkler Cover Plates?

- Customize according to YOUR Drawings

Upon receiving your drawings and brand authorization, our team will immediately verify the details and requirements of the drawings. After mutual communication and confirmation, we will draft a schedule covering mold opening, sample production, testing, final sample approval, and mass production. Based on this timetable, we will efficiently complete the entire process, conducting rigorous quality inspections during production to ensure that you receive satisfactory cover plates as soon as possible.

- Customize based on OUR Existing Models

We offer several popular models compatible with commonly used concealed sprinkler heads on the market. You can micro-customize these models in the following areas: cover plate surface finish, brand engraving, screen print, and personalized brand packaging etc.. The benefits of micro-customization include minimal investment and quick turnaround time, enabling you to enhance your brand reputation in the market efficiently.

- Customize cover plate Surface Finish

For cover plates, we offer a wide range of surface treatments. The most commonly used in practical applications are white coated, chrome plated, and bright brass. You can choose from the following customization options based on your specific requirements:

- Metallic finishes: chrome plated, brushed chrome, bright brass, brushed brass

- Powder coated finishes: white coated, black coated, and other specified colors

Why Choose Sprinkler Cover Plates from SD FIRE SPRINKLER?

SD FIRE SPRINKLER is the specialized manufacturer of fire sprinkler systems since 1997. Our team is well equipped to provide you with professional advice, high-quality products, and customized solutions.

Efficient & Professional Team:

Our team can quickly provide you with customized solutions, promptly respond to and address any questions or issues you may encounter during the customization process, and flexibly meet your customization needs.

Extensive Product Experience:

With over 25 years of manufacturing experience and partnerships with top brands, our accumulated expertise greatly reduces issues in the customization process and ensures consistent product quality.

Flexible Customization:

We offer a wide range of customization options for our cover plates, allowing them to blend seamlessly with any interior design. Whether you need a specific finish or style, we can accommodate your needs, making sure functionality and aesthetics go hand-in-hand.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Fire Sprinkler Cover Plates

What are Fire Sprinkler Cover Plates?

A fire sprinkler cover plate, often called a concealer, escutcheon cap, or ceiling plate, is an integral part of concealed sprinklers. It is designed to provide a neat and smooth appearance by fitting flush with the ceiling or wall, concealing the sprinkler head. The plate is fixed to the retainer by a temperature-sensitive solder that melts at a designated temperature, typically 20 degrees lower than the sprinkler activation point, ensuring timely exposure of the sprinkler head in case of fire. These plates come in various finishes, such as white, chrome, or black, to complement the building’s interior design requirements.

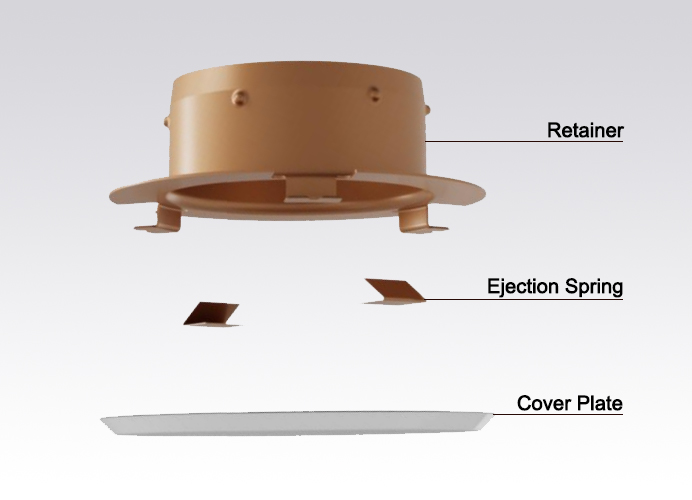

(The term “fire sprinkler cover plate” here refers to a cover plate assembly, which includes a cover plate, a strainer, and ejection springs.)

Sprinkler cover plates and sprinkler escutcheons are frequently confused, but it’s important to note that they are different products. For more information about sprinkler escutcheons, please refer to another article titled “All You Need to Know about Fire Sprinkler Escutcheons“.

Why Use Sprinkler Cover Plates?

Function 01:

It conceals the sprinkler head, maintaining a smooth appearance with the ceiling or wall.

Function 02:

It acts as a protective barrier, safeguarding the sprinkler from dust, debris, and mechanical damage.

Function 03:

Its “push-on” or “thread-off” designs facilitate easy installation after system testing and ceiling finishing.

Cover Plats Types

Fire sprinkler cover plates come in various types, categorized by shape, surface design, and installation method.

Cover Plates By Shapes:

- Round

These are the most common type, providing a classic and compact look.

- Square

Alternatively, square cover plates offer a larger cover surface compared to their round counterpart.

Cover Plates By Plate Design:

- Flat

Flat cover plates provide a smooth appearance on the ceiling or wall after installation, making them widely used.

- Domed

Domed cover plates also offer a neat appearance. Their protruding design provides a slight adjustment range, which helps resolve situations where some sprinklers may protrude from the ceiling or wall.

Cover Plates By Installation Method:

- Thread-on

These cover plates are screwed onto the sprinkler support cup. This thread-on design ensures a more secure installation.

- Push-on

These cover plates are simply pushed onto the sprinkler support cup, making the installation more effortless and convenient.

- Twist-lock

The retainer and support cup of the cover plates feature a snap design. During installation, the cover plate assembly can be twisted and snapped into place, making the installation process relatively effortless.

Other Types:

- Customize

For other special types not included in the previously mentioned categories, please consult a professional manufacturer for technical support.

Cover Plate Structure & Material

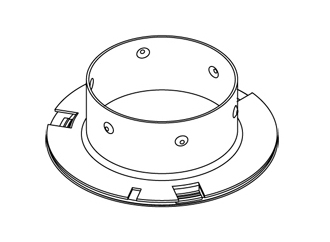

Structure:

The cover plate assembly typically comprises a cover plate and a retainer, often supplemented with two ejection springs. The ejection springs are used to assist the cover plate in detaching during a fire incident, ensuring that concealed sprinkler heads can function properly by spraying water to extinguish the fire.

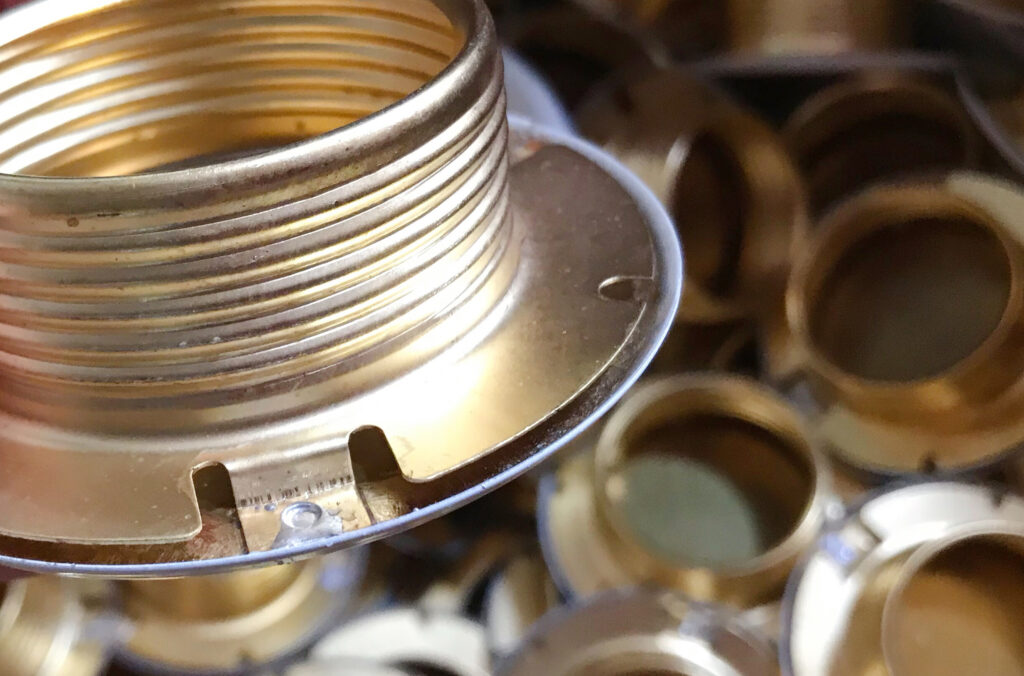

Materials:

- Cover plate: Brass is commonly used, but sometimes stainless steel is adopted.

- Retainer: Brass is generally used

- Ejection spring: Bronze or Stainless Steel or Nickel Alloy

Cover Plate Surface Treatment

White powder coating is the most commonly used surface finish for cover plates. However, to accommodate diverse design requirements, many other surface finish options are available. They can be divided into three main categories: metallic finish, powder-coated finish, and wood-grain finish.

Metallic Finish:

Chrome plated, brushed chrome, bright brass, brushed brass, or customized.

Chrome Plated

Brushed Chrome

Bright Brass

Brushed Brass

Powder-coated Finish:

White coated, ivory coated, black coated, brown coated and other specified colors.

White Coated

Ivory Coated

Black Coated

Brown Coated

Wood-grain Finish:

beige birch, golden pine, warm maple, dark walnut, or customized.

Beige Birch

Golden Pine

Warm Maple

Dark Walnut

Cover Plate Working Temperature

The cover plate must activate no later than the sprinkler to allow for prompt water discharge. Typically, most sprinklers are matched with a cover plate that has a lower activation temperature, usually by 7°C or more. For example, for a common 68°C sprinkler, a 59°C or 57°C cover plate is used. Currently, cover plates with temperatures of 57°C, 59°C, and 74°C are commonly available and can fit most concealed sprinklers.

When selecting or customizing a cover plate, ensure its operating temperature is slightly lower than the corresponding sprinkler’s. This allows the cover plate to fall off first in a fire, enabling the sprinkler to activate promptly and effectively.

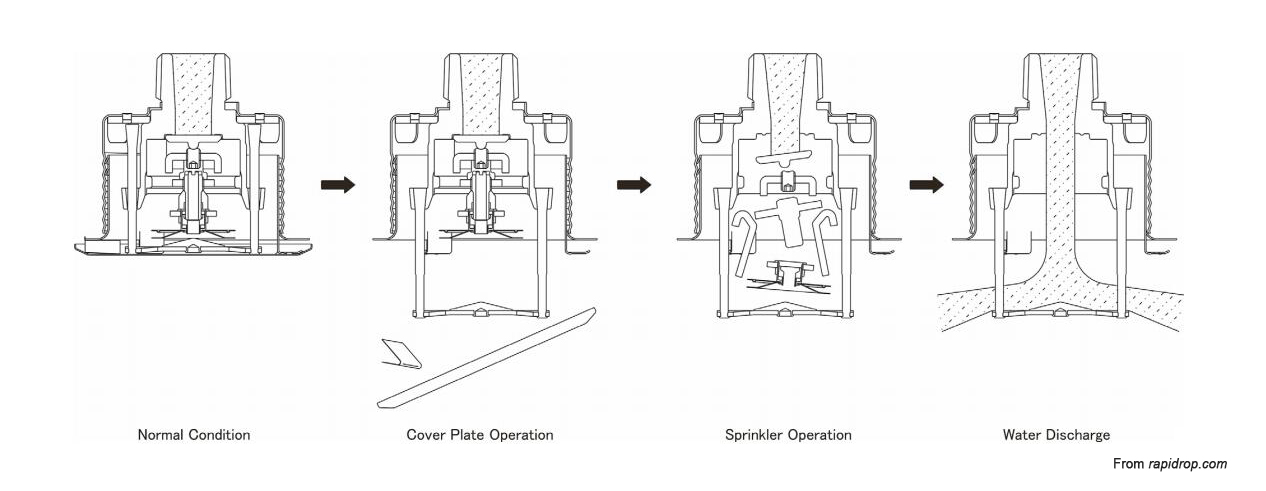

Cover Plate Operation

When a fire occurs, the surrounding temperature rises. As it approaches the sprinkler head’s activation point, the cover plate, typically soldered at three points to the retainer, will detach as the solder melts. This exposes the sprinkler head and the support cup assembly. With further temperature increase, the sprinkler activates and immediately discharge water to extinguish fire.

- For glass bulb sprinklers, the liquid inside the bulb expands when heated. Upon reaching the rated temperature, the liquid expands enough to shatter the glass bulb, thereby activating the sprinkler head and releasing water.

- Fusible element sprinklers work similarly. When the fusible element reaches its rated temperature, it melts and separates, causing the sprinkler to flow water.

How to Choose the Right Cover Plates?

As part of the concealed sprinkler, the cover plate assembly should be chosen with consideration for both its compatibility with the sprinkler head and the design of the installation environment. Additionally, local market standards and usage preferences should be taken into account. Here are the key factors to focus on based on different needs:

Customized Cover Plate Procurement

If you need to customize concealed sprinklers or separately customize a cover plate assembly for a sprinkler head, you can refer to the following steps for the customization process.

1. Compatibility

The first and foremost step is to ensure that the custom cover plates fit your sprinkler heads properly. This involves verifying two critical aspects:

Sprinkler Head Thread Size:

Make sure the thread size of the sprinkler head matches the cover plate assembly & support cup. Support cups are typically custom-made together with cover plates.

Sprinkler Head Height:

The height of the sprinkler head should be compatible with the cover plate design to ensure a snug fit and optimal performance.

2. Aesthetics

Next, decide on the aesthetic features of the cover plate to match your interior design preferences. This includes choosing the plate shape, design, and surface finish.

Plate Shape: Cover plates typically come in two shapes: Round and Square

Plate Design: The design can be either: Flat or Domed

Surface Finish: The finish of the cover plate plays a significant role in its visual appeal. Please refer to the “Cover Plate Surface Treatment” part for reference.

3. Installation

The installation method of the cover plate should align with the preferences of your target market. The common installation methods include:

Thread-On: This method involves screwing the cover plate onto the sprinkler head. It offers a secure and stable fit.

Push-On: This method allows for a quicker installation as the cover plate is pushed onto the sprinkler head. It’s convenient and easy to use.

4.Brand

Finally, consider the branding aspects of the cover plate. Custom branding can enhance the perceived value and recognition of your product.

Brand: Confirm whether the brand should be displayed on the cover plate, and if so, whether it should be stamped, laser-marked, or screen-printed.

Label: Confirm whether a label containing the brand, model, and specifications should be attached.

Package: Confirm if a custom packaging design is required.

Specific Project Procurement

For projects requiring the installation of concealed sprinklers, select units that meet the design specifications, parameters, certification standards and also the budget. Usually, the cover plate is included with the concealed sprinkler, so there’s no need for a separate selection. If there are specific requirements for the cover plate, such as custom surface colors and patterns to match the ceiling, you can request these customization from the sprinkler manufacturer.

Replacement Procurement

If you need to replace the original cover plate, the process is straightforward. The key rule to remember is that each concealed sprinkler has a specific cover plate designed for it. To identify the right one, check the sprinkler head. You’ll usually find the brand or logo on the sprinkler body, and the model and activation temperature on the deflector. Share this information with the sprinkler manufacturer or supplier to get the correct cover plate.

How to Install & Replace Cover Plates?

How to Install Cover Plates?

Installing cover plates for fire sprinklers ensures both safety and a clean, finished look. Follow these steps for a smooth installation:

Step 1: Prepare Your Space

Ensure the sprinkler system is installed and tested.

Repair any leaks and complete the wall or ceiling finish, including painting.

Step 2: Remove the Protective Cap

Carefully remove the plastic cap from the sprinkler head to expose it.

Step 3: Prepare the Cover Plate

Take the cover plate out of its packaging, making sure not to damage any parts.

Step 4: Align the Cover Plate

Position the cover plate base over the sprinkler head, aligning it with the opening in the ceiling or wall.

Step 5: Secure the Cover Plate

Gently push or screw the cover plate onto the sprinkler head.

Apply even pressure with your hand until the cover plate is flush with the ceiling or wall surface.

If necessary, adjust the sprinkler nipple to ensure a proper fit.

How to Replace Cover Plates?

Replacing a cover plate involves removing the old one and installing a new one. Follow these steps to ensure a proper replacement:

Step 1: Remove the Old Cover Plate

Depending on the type, either unscrew or gently pull the existing cover plate off the sprinkler head.

Step 2: Prepare the New Cover Plate

Remove the new cover plate from its packaging, ensuring it remains undamaged.

Step 3: Position the New Cover Plate

Place the new cover plate base over the sprinkler head, aligning it with the ceiling or wall opening.

Step 4: Attach the New Cover Plate

Carefully push or screw the new cover plate onto the sprinkler head.

Use consistent, even pressure until the cover plate sits flush with the surface of the ceiling or wall.

Special Notes for Cover Plates:

*Do Not Modify the Cover Plate: Any alterations to the cover plate can compromise its functionality and the effectiveness of the sprinkler system. Always use the cover plate exactly as provided by the manufacturer.

*Replace Fallen Cover Plates: If a cover plate falls off, do not attempt to glue or caulk it back onto the sprinkler. Replace it with a new cover plate immediately to ensure proper function and safety.

*Avoid Painting the Cover Plate: Do not paint the cover plate, as this can interfere with its thermal sensitivity and ability to release during a fire. Use only pre-finished cover plates supplied by the manufacturer.

Frequently Asked Questions

Find Answers to Nearly All Your Sprinkler Cover Plates Queries Here.

A fire sprinkler cover plate is a decorative element that conceals the sprinkler head, providing a clean and aesthetically pleasing look while ensuring the sprinkler system remains functional.

To install a cover plate, remove the protective cap from the sprinkler head, align the cover plate with the opening, and push or screw it into place until it sits flush with the ceiling or wall.

Remove the old cover plate by unscrewing or pulling it off. Align the new cover plate with the sprinkler head and push or screw it into place, ensuring it sits flush with the surrounding surface.

No, you should never paint the cover plate yourself. Cover plates on concealed sprinklers that have been painted by anyone other than the sprinkler manufacturer must be replaced. Painting the cover plate can interfere with its thermal sensitivity and ability to release during a fire, compromising the effectiveness of the sprinkler system.

If a cover plate falls off, check for any damage to the plate or the sprinkler head. Reattach it by aligning it with the sprinkler head and pushing or screwing it back into place. If it doesn’t stay secure, replace it with new one.

No, modifying a cover plate can affect the sprinkler’s functionality and void its certification. If adjustments are needed, re-cut the sprinkler nipple or consult with a professional for proper fitting solutions.

Cover plates are designed to detach in advance in the event of a fire, allowing the sprinkler to operate properly. If installed correctly and not obstructed, they will not affect the performance of the sprinkler system.

Yes, there should be a small air gap between the lip of the cover plate and the ceiling or wall. This gap allows heat from a fire to reach the solder spots on the cover plate, ensuring it releases promptly during an emergency. This timely release enables the sprinkler head to activate and distribute water effectively.

Request A Free Quote

Our expertise is here to serve you!

We'de like to work with you!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right sprinkler escutcheons you want.

- Tel: +86-574-62357189

- Mob: +86-18867874188

- Email: info@shundanfire.com